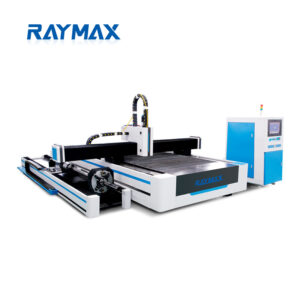

A laser tube cutting machine is a type of automatic CNC metal cutter for square, round and special-shaped pipes made of stainless steel, carbon steel, mild steel, galvanized steel, iron, copper, brass, and aluminum, which is used for straight cutting, tangent, bevel cutting, perforation, 45 degree angle cutting, joint cutting, bevel splicing, and more metal pipe cutting projects & plans. A laser tube cutter is an automatic CNC pipe cutting system that uses laser beam to cut square tubes, round tubes, oval pipes, rectangular tubes, triangular tubes, hexagonal tubes, elliptical tubes and some custom special shape pipes made of carbon steel, stainless steel, tool steel, mild steel, aluminum, alloy, brass, bronze, copper and titanium. A laser metal tube cutter machine is a dieless cutting system to cut any types of designs on metal pipes in any angle and direction. Compared with plasma cutting, flame cutting, water jet cutting, and wire cutting, the precision of laser-cut metal is much higher without grinding.

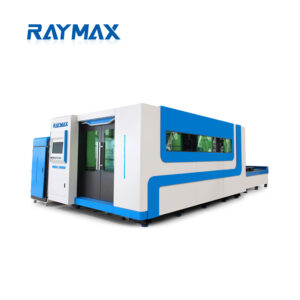

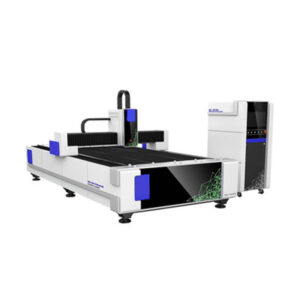

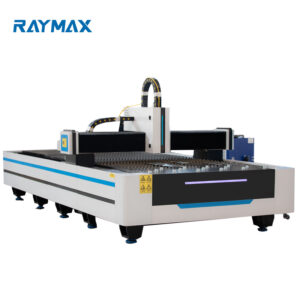

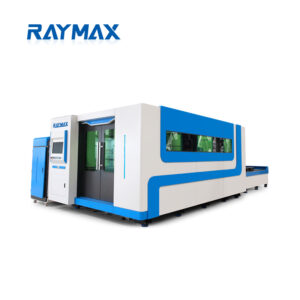

For cutting holes or end profiles in lengths of tubing or pipes, RAYMAX offers the Automatic Tube Cutting Fiber Laser System. This system integrates material handling with the fiber laser to provide a complete work flow solution. The system can accommodate round, square, oval, triangular or special section tubes in a wide variety of materials.

A RAYMAX Tube Cutting Laser can greatly simplify your tube production process by eliminating manufacturing operations such as marking out, sawing, drilling, deburring and shaping that are usually required in tube processing.

Many of RAYMAX’s tube laser-cutting systems integrate intelligent machine functions which include intelligent monitoring, setup and cutting functions. These automated functions improve ease of operation and machine efficiency. The extensive range of capabilities of RAYMAX’s tube and pipe lasers makes these machines ideal for many industries and a variety of applications.